The manufacturing of plastic pollutes our air, and its waste pollutes our environment.

In the ocean, microplastic particles may have started to outnumber zooplankton, and we humans are unintentionally eating a credit card’s worth of plastic every week.

Solving the issue won’t be easy, but some scientists believe they have found the key: breeding something than can eat it.

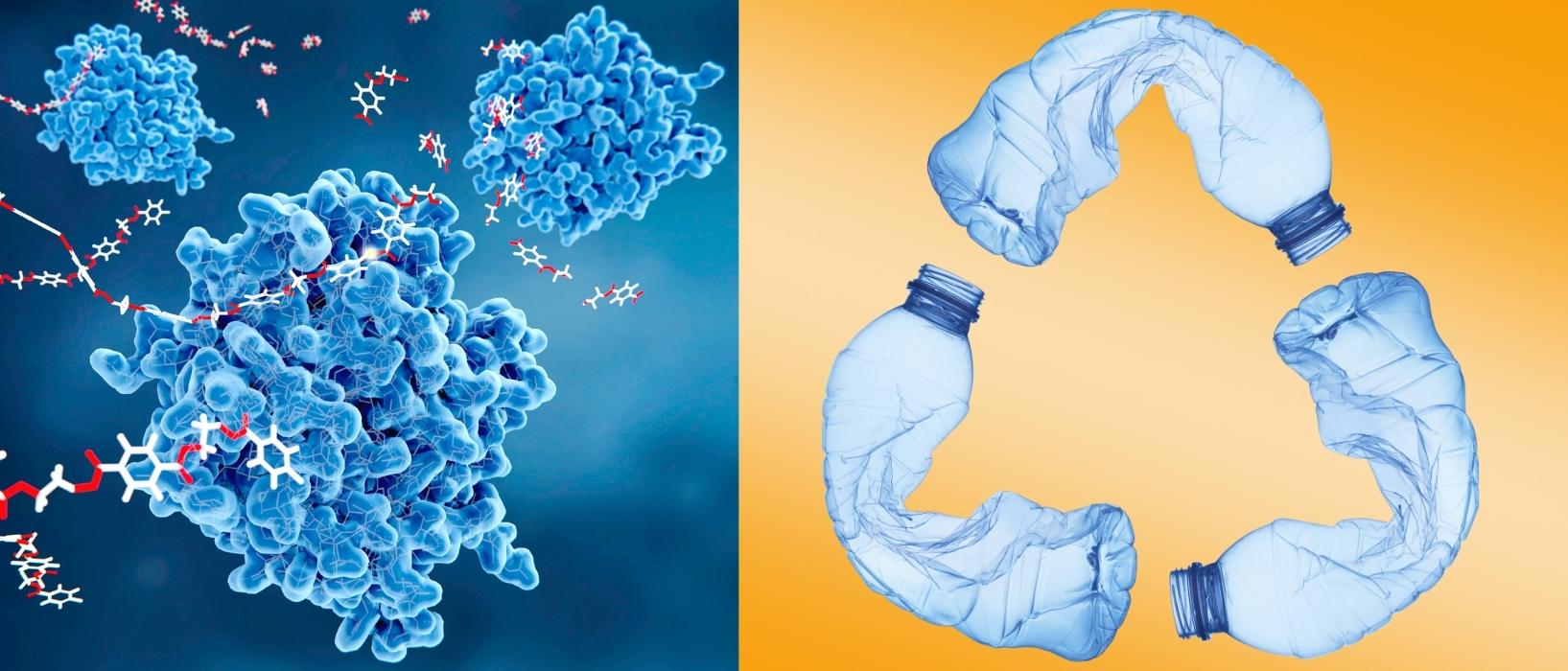

Engineers at the University of Texas have now developed an enzyme which was able to complete a ‘circular process’ of breaking down the plastic and chemically putting it back together in as little as 24 hours.

Developed from a neutral PETase that allows bacteria to degrade and modify plastic, it targets PET, a widely-used polymer that makes up 12% of all global waste.

The scientists used a machine learning model to figure out what mutations would cause the enzyme to be able to quickly break down certain types of plastic waste. They named the new version Functional, Active, Stable, and Tolerate PETase, or FAST PET-ase for short.

“The possibilities are endless across industries to leverage this leading-edge recycling process,” said Hal Alper, professor in the McKetta Department of Chemical Engineering at UT Austin.

“Beyond the obvious waste management industry, this also provides corporations from every sector the opportunity to take a lead in recycling their products. Through these more sustainable enzyme approaches, we can begin to envision a true circular plastics economy.”

Join the Climate Positive Movement

This is not the first time plastic-eating bacteria have been studied. It all began in 2016 when Japanese researchers stumbled upon a bacteria known as Ideonella sakaiensis that, they marvelled, would “eat” the plastic outside of an Osaka bottle factory until it turned into sludge.

By 2020, scientists at the University of Portsmouth had managed to alter the PETase enzyme to create a “cocktail” that could digest plastic up to six times faster than normal.

The new study, published in Nature, goes a step further. The latest version of the enzyme doesn’t need extreme heat or cold to work like the others. Instead, it functions well at ‘normal’ temperatures.

The team now plan to start work on scaling up the enzyme production to prepare it for industrial and environmental application on real-world plastic waste.

A patent application has been filed for the technology, and the scientists are eying several different uses, with cleaning up landfills and greening high waste-producing industries the most obvious.

But another key potential use is environmental remediation, with the hope that in future the enzymes could be sent out into the field to clean up polluted sites.

Be Part of the Climate Solution

Find out how Play it Green can help you